Additive Manufacturing in Defense: Latest Advances Explained

The latest advances in additive manufacturing are revolutionizing defense applications by enabling faster prototyping, lightweighting, and on-demand production of complex parts and systems for enhanced tactical and operational capabilities.

The landscape of modern defense is constantly evolving, driven by the imperative for faster innovation, superior performance, and adaptable supply chains. In this context, additive manufacturing, often referred to as 3D printing, has emerged as a transformative force, fundamentally reshaping how defense items are designed, produced, and maintained.

The Strategic Imperative for Additive Manufacturing in Defense

The defense sector operates under unique pressures, demanding materials and components that can withstand extreme conditions, perform reliably, and be deployed rapidly. Traditional manufacturing processes, while robust, often struggle to meet the pace of modern warfare and the complexities of cutting-edge defense systems. Additive manufacturing offers a compelling alternative, promising unprecedented design freedom and production agility.

The shift towards additive manufacturing is not merely an incremental improvement; it represents a paradigm change, addressing critical challenges faced by defense organizations worldwide. This technology allows for the creation of intricate geometries and custom parts that were previously impossible or prohibitively expensive to produce using conventional methods.

Enhanced Design Freedom and Performance

One of the most significant advantages additive manufacturing brings to defense is the ability to create highly optimized designs. Unlike subtractive methods that remove material, additive processes build parts layer by layer, enabling complex internal structures and integrated functionalities.

-

Lightweighting

Utilizing lattice structures and topology optimization, additive manufacturing can significantly reduce the weight of components. This is crucial for aerial systems, ground vehicles, and soldier-borne equipment, directly translating into improved fuel efficiency, increased payload capacity, and enhanced maneuverability. For instance, an aircraft part redesigned with internal lattice structures can maintain its strength while weighing considerably less.

-

Part Consolidation

Complex assemblies previously requiring multiple components can be consolidated into a single, additively manufactured part. This reduces the number of connections, simplifies assembly, lowers inventory costs, and inherently increases reliability by eliminating potential failure points. Imagine a hydraulic manifold, traditionally a complex puzzle of machined and welded pieces, becoming a single, seamless print.

These capabilities contribute directly to superior system performance, allowing for faster, more agile, and more efficient defense assets. The iterative nature of 3D printing also means that design changes can be implemented swiftly, shortening development cycles dramatically and keeping pace with evolving threats.

The strategic imperative for additive manufacturing in defense extends beyond just individual component improvements. It encompasses a broader vision of resilient supply chains and rapid response capabilities.

By bringing production closer to the point of need, defense organizations can reduce their reliance on distant manufacturing facilities and complex logistics networks, which are vulnerable in contested environments. This regionalized manufacturing capacity strengthens national security and ensures operational readiness.

Advanced Materials for Extreme Environments

The success of additive manufacturing in defense applications hinges heavily on the development and qualification of advanced materials. Defense platforms operate in some of the most demanding environments on Earth, from the vacuum of space to the depths of the ocean, and parts must withstand immense stresses, extreme temperatures, and corrosive agents. Innovations in material science are expanding the possibilities for 3D printing in this sector.

Traditionally, high-strength metals and advanced polymers were manufactured using casting, forging, or machining. Additive manufacturing now offers processes to work with these same materials, and even new, tailor-made alloys and composites, yielding parts with comparable or superior mechanical properties.

The ability to precisely control the microstructure of materials during the additive process opens up new avenues for performance optimization. For example, specific heat treatments or modifications to print parameters can yield parts with anisotropic properties, meaning they are stronger in certain directions—a critical advantage for components under directional loads.

Metals and Superalloys

The printing of high-performance metals like titanium alloys, nickel-based superalloys, and specialized steels is critical for aerospace components, jet engine parts, and naval applications. These materials offer exceptional strength-to-weight ratios and high-temperature resistance.

-

Titanium Alloys (Ti-6Al-4V)

Widely used in aerospace for its outstanding strength, low density, and corrosion resistance. Additive manufacturing of titanium enables complex, lightweight structural components for aircraft and missiles, offering significant performance gains over conventionally manufactured parts.

-

Nickel Superalloys (Inconel 718, Hastelloy X)

Essential for high-temperature applications such as jet engine components, rocket nozzles, and exhaust systems. These alloys retain their strength and integrity at extreme heat, making additive manufacturing a game-changer for propulsion systems, where intricate cooling channels and optimized flow paths can be integrated.

The development of new metal powders specifically designed for additive processes is also accelerating. These powders are engineered to flow better, melt more consistently, and cool in a way that minimizes defects and improves the final part’s integrity.

Advanced Polymers and Composites

Beyond metals, advancements in polymer and composite additive manufacturing are enabling a new generation of lighter, functional, and even smart components for defense systems. These materials are crucial for applications where weight is paramount or where specific electrical and thermal properties are required.

-

High-Performance Polymers (PEEK, ULTEM)

These thermoplastics offer excellent thermal, mechanical, and chemical resistance. They are increasingly used for lightweight structural components, housings for electronics, and even insulators in harsh environments. Their ability to retain properties at high temperatures makes them suitable for parts close to engine bays or exposed to high friction.

-

Carbon Fiber Reinforced Composites

Integrating carbon fibers directly into 3D-printed polymer matrices creates parts with significantly enhanced strength and stiffness while remaining exceptionally light. This is particularly valuable for unmanned aerial vehicles (UAVs), body armor, and custom brackets, where conventional composite manufacturing can be labor-intensive and require expensive tooling.

The evolution of multi-material printing capabilities is also a significant trend, allowing for the combination of different material types within a single print. This could mean embedding sensors directly into a structural component or creating parts with varying flexibility or conductivity across their geometry, leading to truly smart and adaptive defense systems.

The continuous innovation in material science for additive manufacturing is directly addressing the stringent requirements of the defense sector, enabling the development of parts that are not only stronger and lighter but also smarter and more resilient to the challenges of modern defense operations.

On-Demand Manufacturing and Supply Chain Resilience

One of the most profound impacts of additive manufacturing on the defense industry is its potential to revolutionize logistics and supply chain management. The ability to print parts on demand, anywhere in the world, offers unprecedented resilience and responsiveness, reducing reliance on long, vulnerable supply lines and extensive physical inventories.

Traditional defense supply chains are notoriously complex, with parts often manufactured globally and shipped across continents. This creates vulnerabilities to disruption, whether from geopolitical events, natural disasters, or simple manufacturing delays. Maintaining vast stockpiles of spare parts is also incredibly costly and inefficient.

Additive manufacturing provides a compelling solution to these challenges by enabling localized, decentralized production. A forward operating base, a naval vessel, or even a field hospital could theoretically print critical spare parts as needed, drastically reducing downtime and improving operational readiness.

This localized production capability also offers a strategic advantage. It means less reliance on specific manufacturers or countries for critical components, enhancing national security and reducing the risk of supply chain weaponization.

Reduced Lead Times and Inventory Costs

The conventional procurement process for defense parts can be lengthy, involving design, tooling, manufacturing, and shipping. Additive manufacturing compresses this timeline significantly, especially for small-batch production or unique components.

-

Rapid Prototyping

Design iterations can be tested and refined much faster. Instead of waiting weeks or months for a machined prototype, a 3D-printed version can be produced in hours or days, accelerating the development cycle for new systems and modifications. This speed allows for quicker validation of new concepts and faster deployment of upgrades.

-

Minimized Obsolescence and Warehouse Needs

Manufacturing parts on demand dramatically reduces the need to store large inventories, particularly for older or less frequently used components that are prone to obsolescence. Instead of maintaining warehouses full of physical parts, defense organizations can maintain digital inventories of part designs, printing them only when required. This frees up valuable storage space and reduces the financial burden of managing aging inventory.

The concept of a “digital warehouse” where blueprints are stored instead of physical items is becoming a reality, offering immense logistical flexibility. This approach also allows for continuous updates to part designs, ensuring that even replacement parts incorporate the latest improvements.

Forward Deployment and Battlefield Repair

The ability to deploy additive manufacturing capabilities directly to operational theaters can be a game-changer for battlefield logistics and repair. Imagine repairing a damaged drone part or a vehicle bracket in a remote location, rather than waiting for a replacement to be shipped from thousands of miles away.

Mobile 3D printing units, whether containerized or integrated into specialized vehicles, are becoming increasingly feasible. These units can produce custom tools, fixtures, and even functional components, supporting immediate repair and maintenance needs, thereby increasing the operational availability of critical equipment. This shifts the focus from “replace” to “repair,” which is particularly vital for sustaining lengthy operations.

The implications of on-demand manufacturing extend to humanitarian aid and disaster relief operations as well, where rapid production of medical supplies, shelter components, or water purification parts can be critical. The agility offered by additive manufacturing transforms the very nature of defense logistics, making it more resilient, responsive, and ultimately, more effective in supporting military operations worldwide.

Qualification and Certification Challenges

While the benefits of additive manufacturing are clear, integrating this technology into the stringent defense sector brings significant challenges, particularly concerning part qualification and certification. Unlike traditional manufacturing, where processes are well-established and materials extensively characterized, additive manufacturing introduces complexities in ensuring consistent quality, reliability, and performance.

Every defense component produced must meet extremely high standards for safety, durability, and mission-critical functionality. This necessitates rigorous testing and validation, a process that can be time-consuming and expensive for additively manufactured parts due to their unique properties and process variability.

The primary concern stems from the layer-by-layer nature of additive processes, which can introduce anisotropic properties (properties that vary with orientation), residual stresses, and micro-defects if not precisely controlled. Verifying that a 3D-printed part will perform identically to a traditionally manufactured one under extreme conditions is a complex scientific and engineering endeavor.

Developing Robust Standards and Protocols

To overcome these hurdles, there is an urgent need to develop universally accepted standards and protocols for additive manufacturing in defense. These standards must address everything from material specifications and machine parameters to post-processing treatments and inspection methods.

-

Process Validation

Ensuring that the entire 3D printing process—from powder quality to final heat treatment—is robust and repeatable. This involves meticulous documentation and statistical process control to minimize variability between prints.

-

Material Qualification

Thoroughly characterizing the mechanical, thermal, and chemical properties of additively manufactured materials. This often means testing materials produced with slightly different parameters to establish acceptable operating windows and understand how process variations impact performance.

-

Non-Destructive Testing (NDT)

Developing advanced NDT techniques specifically tailored for 3D-printed parts, which may have internal geometries or material structures that are difficult to inspect using conventional methods. Techniques like X-ray computed tomography (CT scanning) are crucial for internal defect detection.

Collaboration between government agencies, industry, and academia is vital to accelerate the development of these standards. Sharing research data, best practices, and lessons learned will help to build confidence in the technology and streamline the qualification process.

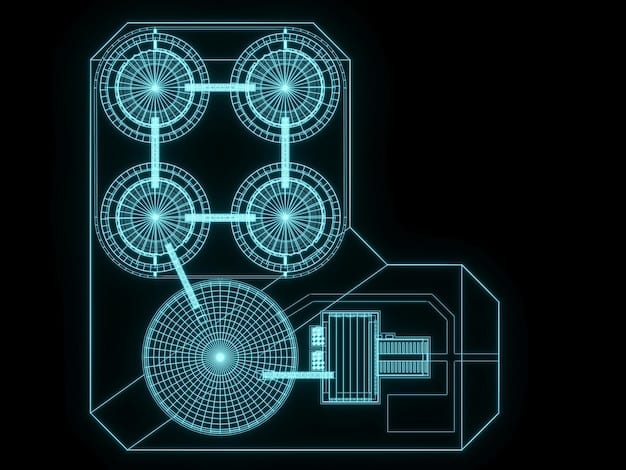

Digital Twin and In-Situ Monitoring

Emerging technologies like “digital twins” and in-situ process monitoring are playing a crucial role in addressing qualification challenges. A digital twin is a virtual replica of a physical part, created using advanced simulations and sensor data from the manufacturing process.

In-situ monitoring involves embedding sensors directly into the 3D printer to collect data on temperature, laser power, melt pool dynamics, and other parameters during the printing process. This real-time data allows for immediate detection of anomalies and informs predictive models of part quality. Combined with a digital twin, this enables a comprehensive understanding of how a part was built and how it is expected to perform.

This data-driven approach to qualification builds confidence in additive manufacturing by providing auditable records of every step of the production process. Ultimately, overcoming qualification and certification challenges is not just about ensuring safety and performance; it’s about enabling wider adoption and unlocking the full potential of additive manufacturing for critical defense applications.

Application Areas and Success Stories

Additive manufacturing is no longer a futuristic concept in defense; it is actively being deployed across a wide range of applications, demonstrating tangible benefits in performance, cost, and readiness. From prototyping to end-use components, the success stories are accumulating, proving the technology’s worth across air, land, and sea domains.

The versatility of additive manufacturing allows for its application in diverse areas, from highly specialized, mission-critical components to simple tools and fixtures that improve efficiency. This broad applicability underscores its transformative potential for the entire defense ecosystem.

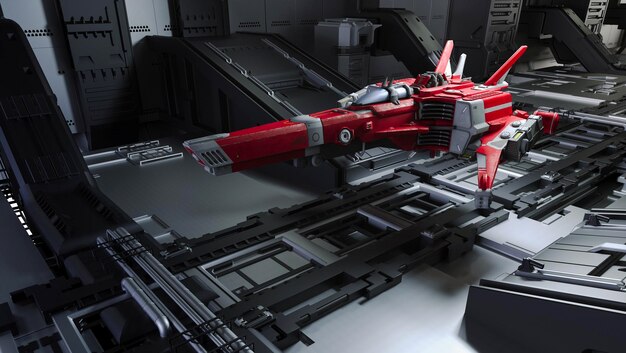

Aerospace and Aviation

Perhaps no sector has embraced additive manufacturing as enthusiastically as aerospace, where lighter components directly translate to fuel savings and increased range. For military aircraft, this means extended mission times and greater operational reach.

-

Engine Components

Complex parts like fuel nozzles, turbine blades, and heat exchangers are being additively manufactured for various military aircraft and missile systems. The ability to create intricate internal cooling channels drastically improves efficiency and performance. For example, GE Aviation has been a pioneer in 3D printing fuel nozzles for its F414 and F110 engines, which power fighter jets like the F/A-18 Super Hornet and F-15 Eagle.

-

Structural Parts

Lightweight brackets, ducts, and airframe components for combat aircraft and drones are being 3D printed from high-strength alloys. These parts reduce overall aircraft weight, improving agility and payload capacity. Lockheed Martin, for instance, has leveraged additive manufacturing for parts on the F-35 Lightning II, reducing component count and weight.

The rapid prototyping capabilities are also invaluable in aerospace, allowing for quick iterations of new designs for next-generation combat aircraft and uninhabited aerial systems (UAS), leading to faster development cycles for critical air superiority assets.

Naval and Maritime Applications

The challenging marine environment demands robust parts that can withstand corrosion, high pressures, and constant vibration. Additive manufacturing offers solutions for naval vessels, submarines, and autonomous uncrewed surface/underwater vehicles (USVs/UUVs).

-

Spare Parts and Repairs

The U.S. Navy has been at the forefront of deploying 3D printers on ships and submarines to produce on-demand spare parts, tools, and custom fixtures. This significantly reduces the logistical tail and ensures vessels remain operational during long deployments. Instances include printing replacement covers, pipe fittings, and even mission-specific sensor housings.

-

Propulsion and Hull Components

Research and development are ongoing for additively manufacturing components for ship propulsion systems and specialized hull structures, which could lead to significant reductions in manufacturing time and costs, and potentially improved hydrodynamic efficiency. The ability to print large metal parts means increasingly complex and performance-optimized marine structures are becoming a reality.

The localized repair capability offered by additive manufacturing is particularly critical for naval forces, operating far from traditional supply depots, enhancing fleet readiness and deployability.

Ground Systems and Soldier Modernization

For land-based defense and individual soldier systems, additive manufacturing provides solutions for customized gear, vehicle components, and specialized tools, enhancing resilience and effectiveness.

-

Custom Tools and Fixtures

Military maintenance crews are using 3D printers in the field to create specific tools or repair jigs that would otherwise require lengthy procurement times, improving vehicle and equipment readiness.

-

Personalized Equipment

From customized helmet padding for improved fit and protection to ergonomically designed weapon grips and specialized mounts for soldier-borne sensors, additive manufacturing allows for mass customization, enhancing soldier comfort and performance.

-

Vehicle Components

The ability to print complex, lightweight parts for armored vehicles, such as specialized brackets, interior components, or even prototype armor elements, can contribute to weight reduction and enhanced protection. The U.S. Army has experimented with printing vehicle parts and even bridges for rapid deployment.

These diverse applications underscore the widespread impact of additive manufacturing on the defense sector, transitioning from a research curiosity to an indispensable tool for maintaining technological superiority and operational readiness across all domains. Each success story builds upon the last, paving the way for even more advanced and integrated additive solutions in the future of defense.

Future Outlook and Emerging Trends

The journey of additive manufacturing in defense is still in its early stages, with significant potential for further growth and integration. The future promises even more sophisticated capabilities, driven by ongoing research, advancements in materials, and continued investment from defense organizations embracing digital transformation.

Several key trends are poised to shape the next generation of additive manufacturing for defense applications, moving beyond simply printing parts towards creating entire functional systems and adapting to dynamic battlefield needs.

One major area of focus will be on further integrating artificial intelligence and machine learning into the additive manufacturing workflow. AI can optimize print parameters, predict part performance, and even automatically design geometries for specific applications, significantly accelerating the design-to-print cycle and reducing human error.

Multi-Material and Hybrid Manufacturing

The ability to print multiple materials within a single component, potentially with varying properties, is a significant emerging trend. This could revolutionize the integration of electronics, sensors, and functional elements directly into structural parts.

-

Integrated Electronics

Imagine a drone wing that is not just structural but also contains embedded antennas, sensors, and wiring printed directly into its layers, reducing assembly complexity and improving reliability. This “additively manufactured electronics” (AME) capability will lead to truly smart structures.

-

Hybrid Manufacturing Systems

Combining additive processes with traditional subtractive methods (like machining) in a single machine tool. This allows for the precise finishing of critical surfaces while leveraging the design freedom of additive manufacturing for complex internal features, offering the best of both worlds for high-precision defense components.

These hybrid approaches address a key limitation of pure additive processes, which sometimes struggle with achieving ultra-smooth surface finishes or extremely tight tolerances without post-processing. Integrated capabilities resolve this, streamlining the overall production workflow.

Large-Scale and High-Volume Production

While additive manufacturing has excelled in low-volume, high-complexity parts, future developments aim to scale up the technology for larger components and higher production volumes, making it viable for a broader range of defense applications.

-

Large-Format Printers

Development of industrial-scale 3D printers capable of fabricating very large structures, such as submarine hull sections, large vehicle components, or even modular shelters, will expand the scope of what can be additively manufactured for defense.

-

Increased Throughput

Innovations in multi-laser systems, faster deposition rates, and parallel processing techniques are increasing the speed and efficiency of additive manufacturing, making it more competitive for medium to high-volume production runs. This also helps in reducing costs per part, which is critical for wider adoption.

The eventual goal is to integrate additive manufacturing into existing production lines, allowing for flexible transitions between conventional and additive methods as needed, depending on the complexity, volume, and urgency of the part required. This adaptability will be key for defense manufacturers to respond quickly to evolving operational demands.

The future of additive manufacturing in defense is one of continued innovation, further integration into the digital thread, and a move towards creating fully functional, smart, and adaptive systems. As these trends mature, 3D printing will undoubtedly become an even more indispensable tool in ensuring tactical superiority and supply chain resilience for national security.

| Key Point | Brief Description |

|---|---|

| 🚀 Design Freedom | Enables complex geometries, lightweighting, and part consolidation for defense without traditional manufacturing limits. |

| ⚙️ Advanced Materials | Utilization of high-performance metals (titanium, superalloys) and composites for extreme defense environments. |

| 📦 Supply Chain Agility | Facilitates on-demand production, reducing lead times, inventory, and enhancing battlefield repair capabilities. |

| 🔬 Qualification Challenges | Requires robust standards, process validation, and advanced NDT for widespread defense adoption. |

Frequently Asked Questions about Additive Manufacturing in Defense

The main benefits include enhanced design freedom for complex geometries, significant weight reduction for vehicles and aircraft, rapid prototyping for faster development cycles, and the ability to produce parts on-demand, which drastically improves supply chain resilience and reduces lead times for critical components.

High-performance metals like titanium alloys (e.g., Ti-6Al-4V) and nickel-based superalloys (e.g., Inconel) are frequently used for their strength and temperature resistance. Additionally, advanced polymers such as PEEK and ULTEM, along with carbon fiber reinforced composites, are employed for lightweight structural parts and specialized equipment.

Additive manufacturing improves supply chains by enabling localized, on-demand production, reducing reliance on traditional manufacturing centers and long shipping routes. This minimizes inventory holding costs, mitigates obsolescence risks, and allows for rapid battlefield repair and part replacement, enhancing operational readiness in remote locations.

Key challenges include rigorous qualification and certification processes for new materials and parts, ensuring consistent part quality and reliability from diverse printers, and developing robust standards across the industry. Overcoming these requires significant research, standardized protocols, and advanced in-situ monitoring technologies.

Emerging trends include multi-material printing, allowing for integrated electronics and sensors within structural components. Hybrid manufacturing systems combine additive and subtractive processes for precision, and there’s a growing focus on scaling up additive manufacturing for larger components and higher volume production, making it more versatile for defense needs.

Conclusion

Additive manufacturing stands as a pivotal technology for the ongoing modernization of the defense industry. Its capacity to deliver unprecedented design flexibility, leverage cutting-edge materials, ensure supply chain resilience, and accelerate innovation cycles positions it as an indispensable tool for future military operations. While challenges in qualification and standardization persist, ongoing advancements and strategic investments underscore a clear trajectory towards broader integration. As the technology matures, it promises to continue enhancing the capabilities of defense forces, ensuring they remain agile, adaptable, and prepared for the evolving complexities of global security challenges.