The Impact of 3D Printing on Military Equipment Production

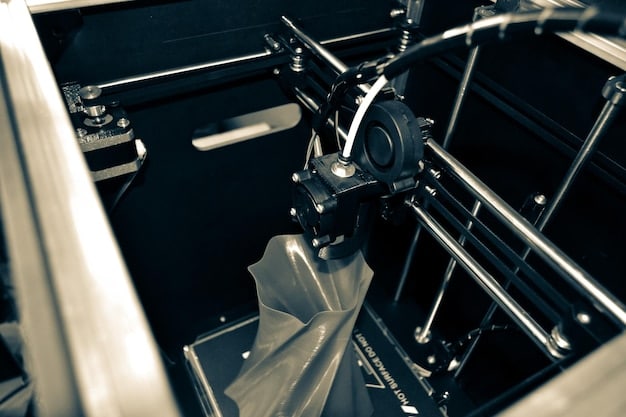

The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production is revolutionizing military operations by enabling faster, more efficient, and customized manufacturing of parts and equipment, enhancing readiness and innovation.

The modern battlefield demands rapid adaptability and technological superiority. One technology playing an increasingly vital role is The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production. But how exactly is it changing the game? Let’s explore the transformative potential of additive manufacturing in the military.

Understanding The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production

Additive manufacturing, commonly known as 3D printing, involves building three-dimensional objects layer by layer from a digital design. This technology offers unparalleled flexibility and efficiency in manufacturing, with significant implications for military equipment production. Now, let’s dive into how this technology is being used and some of the advantages it offers.

Benefits of 3D Printing in Military Applications

3D printing offers unique advantages that are particularly valuable in military contexts, such as:

- Rapid Prototyping: Quickly create and test new designs, accelerating the development of advanced military equipment.

- Customization: Produce tailored parts and tools that meet specific mission requirements, enhancing operational effectiveness.

- On-Demand Production: Manufacture parts at or near the point of need, reducing reliance on traditional supply chains and logistics.

- Cost Savings: Lower production costs for specialized or low-volume parts compared to conventional manufacturing methods.

In summary, additive manufacturing provides a pathway to innovative military solutions, offering streamlined production, customization, and cost-efficiency.

Enhancing Supply Chain Resilience with Additive Manufacturing

Traditional military supply chains can be complex and vulnerable to disruptions. Additive manufacturing offers a solution by enabling decentralized production and reducing reliance on external suppliers. This is particularly relevant when considering The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production.

Reducing Dependency on External Suppliers

By bringing production in-house, the military can mitigate risks associated with geopolitical instability, transportation delays, and supplier unreliability. This shift ensures a more secure and responsive supply chain, leading to:

- Increased Control: Complete oversight of the manufacturing process, ensuring quality and security.

- Reduced Lead Times: Faster access to critical parts and equipment, minimizing downtime and improving readiness.

- Greater Flexibility: Ability to adapt quickly to changing needs and produce parts on-demand.

By adopting additive manufacturing, the military can create a more robust and self-sufficient supply chain, better equipped to handle unforeseen challenges.

Applications of 3D Printing in Military Equipment Maintenance

Maintaining military equipment in peak condition often requires specialized parts that may be difficult to source or expensive to produce using traditional methods. 3D printing addresses these challenges by enabling the rapid and cost-effective creation of replacement parts and customized tools, thus demonstrating The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production.

Creating Custom Tools and Replacement Parts

With the ability to produce parts on-demand, maintenance personnel can quickly address equipment malfunctions and reduce downtime. 3D printing contributes to:

- Extended Equipment Lifespan: Timely replacement of worn or broken parts, preventing further damage and extending the service life of military assets.

- Improved Maintenance Efficiency: Customized tools designed specifically for maintenance tasks, streamlining procedures and reducing errors.

- Reduced Logistics Burden: On-site production of parts, minimizing the need to transport and store a large inventory of spares.

Ultimately, the use of 3D printing in equipment maintenance enables a more efficient and responsive support system, ensuring military readiness and operational effectiveness.

The Role of 3D Printing in Modernizing Military Technology

Innovation is critical for maintaining a competitive edge in modern warfare. 3D printing supports this by enabling the rapid development and testing of new technologies. This is a key example of The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production. With quick prototyping, this allows modernizing current technology to be faster.

Facilitating Rapid Prototyping and Innovation

By shortening the design-to-deployment cycle, the military can quickly incorporate cutting-edge technologies into its arsenal. This ability allows for:

- Faster Development Cycles: Quickly iterate on designs and test new concepts, accelerating the pace of innovation.

- Enhanced Capabilities: Integration of advanced materials and complex geometries, leading to more capable and effective military equipment.

- Competitive Advantage: Staying ahead of adversaries by leveraging the latest technological advancements.

As such, 3D printing drives military modernization, ensuring that armed forces have access to the best possible tools and technologies.

Overcoming Challenges in Additive Manufacturing Adoption

While the benefits of additive manufacturing are clear, successful adoption requires overcoming a number of challenges. These include material limitations, workforce skills gaps, and cybersecurity concerns. Each of these challenges are significant when it comes to The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production.

Addressing Material Limitations and Skills Gaps

To fully realize the potential of additive manufacturing, it is essential to invest in research and development of new materials and to train personnel in the skills required to operate and maintain 3D printing equipment. Some items to consider are:

- Material Development: Expanding the range of materials compatible with 3D printing, including high-strength alloys and advanced polymers.

- Workforce Training: Providing specialized training programs to equip military personnel with the skills needed to design, operate, and maintain 3D printing systems.

- Cybersecurity Measures: Implementing robust cybersecurity protocols to protect digital designs and manufacturing processes from cyber threats.

Through targeted investments and strategic planning, the military can overcome these challenges and unlock the full potential of additive manufacturing.

The Future of Additive Manufacturing in the Military

As the technology continues to evolve, additive manufacturing is poised to play an even greater role in shaping the future of military equipment production. With advancements in printing speed, material properties, and automation, an even more significant The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production will be seen.

Anticipating Future Advancements and Trends

Looking ahead, we can expect to see:

- Increased Automation: Fully automated 3D printing systems capable of producing complex parts with minimal human intervention.

- Advanced Materials: Development of new materials with enhanced properties, such as greater strength, heat resistance, and corrosion resistance.

- Integration with AI and Machine Learning: Use of artificial intelligence and machine learning to optimize designs and manufacturing processes.

The future looks bright for additive manufacturing in the military, offering exciting opportunities to enhance capabilities, reduce costs, and maintain a competitive edge.

| Key Point | Brief Description |

|---|---|

| 🚀 Rapid Prototyping | Accelerates the development of advanced military equipment. |

| 🧰 Customization | Produces tailored parts and tools that meet specific mission needs. |

| 💰 Cost Savings | Lowers production costs for specialized or low-volume parts. |

| 🛡️ Supply Chain Resilience | Reduces dependency on external suppliers and transportation. |

Frequently Asked Questions

Additive manufacturing, or 3D printing, builds objects layer by layer from a digital design. In the military, this means faster creation of custom parts, tools, and equipment, enhancing operational readiness and reducing supply chain vulnerabilities.

The primary benefits include rapid prototyping, customization, on-demand production, reduced logistics costs, and enhanced supply chain resilience. It enables quicker innovation and adaptation to evolving military needs.

3D printing decentralizes production, reducing reliance on external suppliers and traditional logistics. This leads to greater control, shorter lead times, and improved flexibility in meeting military demands efficiently.

Challenges include material limitations, the need for a skilled workforce, and cybersecurity concerns. Overcoming these requires investments in R&D, specialized training, and robust digital protection.

Future trends include increased automation, the development of advanced materials, and the integration of AI and machine learning. These advancements will further enhance capabilities, reduce costs, and maintain a competitive edge.

Conclusion

In conclusion, The Impact of Additive Manufacturing (3D Printing) on Military Equipment Production is profound and far-reaching, promising enhanced capabilities, reduced costs, and a more resilient and responsive defense infrastructure. Embracing and advancing this technology is essential for maintaining military superiority in the modern era.