US Military’s 3D Printing: Rapid Prototyping Weapon Systems

The US military significantly leverages 3D printing for rapid prototyping of weapon systems, enabling accelerated design iterations, on-demand part fabrication, and enhanced operational readiness by quickly transitioning concepts to functional prototypes for field testing and deployment.

In the dynamic landscape of modern defense, the ability to innovate at speed is paramount. The question of How is the US Military Utilizing 3D Printing for Rapid Prototyping of Weapon Systems? reveals a transformative shift in defense manufacturing, moving from traditional, time-consuming processes to agile, additive methodologies. This evolution is reshaping how new weapon systems are conceived, developed, and deployed, offering unprecedented advantages in cost, time, and tactical flexibility across various branches of the US Armed Forces.

Accelerating Innovation: The Strategic Imperative of Additive Manufacturing

The US Department of Defense (DoD) faces an incessant demand for technological superiority and rapid adaptation to evolving threats. Traditional manufacturing methods, often characterized by lengthy supply chains, high tooling costs, and extended lead times, frequently hamper this critical need. This is where additive manufacturing, more commonly known as 3D printing, steps in as a game-changer.

The strategic imperative for adopting 3D printing is clear: it allows for the swift creation of complex geometries directly from digital designs, bypassing many conventional constraints. This capability is not just about making parts faster; it’s about fundamentally altering the design-test-deploy cycle, fostering an environment where innovation can proliferate and be realized at an accelerated pace, ensuring US military forces maintain their competitive edge globally.

From Concept to Combat: The Prototyping Advantage

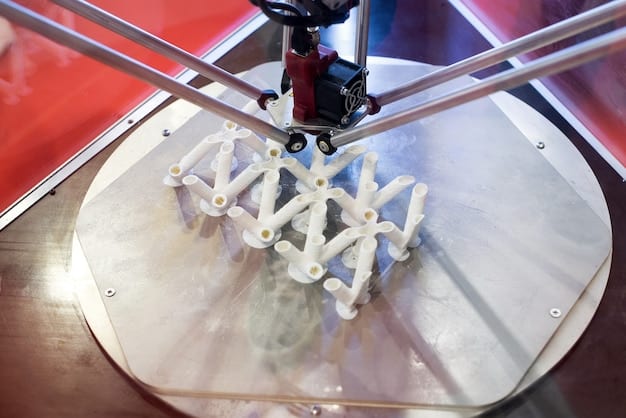

Rapid prototyping is arguably the most significant immediate benefit of 3D printing for weapon systems development. Instead of waiting weeks or months for a machined or molded prototype, engineers can iterate designs in days or even hours. This speed allows for quicker evaluation of form, fit, and function, catching potential issues earlier in the design process and significantly reducing overall development timelines.

The ability to produce multiple design variations quickly means that performance can be optimized more thoroughly before committing to expensive production tooling. This iterative process is crucial for systems that demand high precision and reliability, where even minor design flaws can have significant operational consequences. Furthermore, the capacity to create highly specialized, custom components without extensive setup costs opens doors for bespoke solutions tailored to specific mission requirements.

- Reduced Lead Times: Concepts translate into physical models in hours or days, not weeks.

- Cost Efficiency in Early Stages: Low-volume prototyping is significantly cheaper than traditional methods.

- Enhanced Design Freedom: Complex internal structures and lightweight designs become feasible.

- Iterative Design Cycles: Rapid changes and testing cycles refine performance quickly.

This agility directly contributes to a more responsive defense industrial base, one capable of delivering advanced capabilities to service members at the speed of relevance. It empowers design teams to experiment with revolutionary concepts that might be impractical or too costly to pursue with conventional fabrication techniques.

Beyond Prototypes: Functional Components and Spare Parts On Demand

While rapid prototyping stands as a primary application, the US military’s utilization of 3D printing extends far beyond initial design validation. As additive manufacturing technologies mature, they are increasingly being employed to produce functional components, tooling, and even spare parts, directly supporting operational readiness and battlefield logistics.

The ability to print critical parts on demand, whether in a forward operating base or aboard a naval vessel, drastically reduces reliance on traditional supply chains. This minimizes downtime for equipment, ensuring that weapon systems remain operational and effective, even in remote or austere environments. This distributed manufacturing capability represents a paradigm shift in military readiness, fostering greater self-sufficiency and resilience.

Material Science and Durability for Military Applications

The transition from concept models to functional parts hinges critically on advancements in material science. Early 3D printers were limited to plastics, suitable primarily for non-structural prototypes. However, modern systems can now print with a wide array of high-performance materials, including various metals, advanced polymers, and even composites. These materials possess mechanical properties comparable to, or in some cases superior to, those achieved through traditional manufacturing.

For weapon systems, this means the production of components that can withstand extreme temperatures, high pressures, and corrosive environments. The DoD is actively investing in research and development to qualify new materials and processes for critical applications, ensuring that 3D-printed parts meet stringent military specifications for durability, reliability, and safety. This includes rigorous testing and certification processes to ensure material integrity under operational stresses.

- Metals: Titanium, aluminum, stainless steel for structural and ballistic components.

- High-Performance Polymers: PEKK, Ultem for lightweight, heat-resistant parts.

- Composites: Carbon fiber-reinforced materials for enhanced strength-to-weight ratios.

The ability to create complex internal lattice structures also contributes to weight reduction without compromising strength, a critical factor for aerial platforms and soldier-borne equipment. This optimization of material use translates directly into improved performance and extended operational ranges for weapon systems.

Naval Applications: Submarine Parts and Ship components

The U.S. Navy and Marine Corps are at the forefront of integrating additive manufacturing into their operational and logistical frameworks. The unique challenges of naval operations, including long deployments, limited storage, and remote environments, make 3D printing an ideal solution for maintaining readiness and reducing reliance on traditional supply chains. Onboard 3D printing labs are becoming more common, enabling sailors to print parts as needed, from simple plastic clips to complex metal components.

This capability is particularly beneficial for submarines, where space is at a premium and access to spare parts can be limited during extended missions. By printing parts on-site, crews can address minor repairs or fabricate custom tools quickly, significantly impacting the vessel’s readiness and preventing costly mission aborts. The Navy is also exploring the use of 3D printing for larger, more structural ship components, which could revolutionize shipbuilding and repair processes.

Forward Operating Bases and Field Repairs

For the Army and Marine Corps, 3D printing offers unprecedented capabilities for tactical logistics and field sustainment. In austere or forward operating environments, traditional logistics networks can be slow and vulnerable. Establishing expeditionary additive manufacturing capabilities allows forces to produce mission-critical parts, tools, and even custom equipment on site.

This includes printing replacement parts for broken vehicles, crafting specialized tools for maintenance, or even fabricating custom attachments for existing weapon systems to enhance their functionality in specific scenarios. The immediate availability of these items reduces the need for large inventories of spares, streamlines the supply chain, and empowers units to operate more independently and effectively for longer durations without external support. This decentralized manufacturing model offers significant tactical advantages in contested environments.

Air Force and Army Initiatives: Customization and Optimization

Both the U.S. Air Force and the U.S. Army are leveraging 3D printing to advance their respective capabilities, focusing on aspects unique to air superiority and ground combat. For the Air Force, the emphasis often lies on lightweight, high-performance components for aircraft, as well as rapid tooling and repair solutions to maintain their vast fleet. The Army, meanwhile, focuses on robust and customizable solutions for ground vehicles, soldier equipment, and rapid prototyping of various weapon system adaptations.

The ability to print complex parts for legacy aircraft, for which spare parts may no longer be manufactured conventionally, significantly extends their operational life. This not only saves immense costs but also ensures that critical assets remain airworthy. For new aircraft, 3D printing enables novel designs that optimize aerodynamics and reduce weight, directly impacting fuel efficiency and performance. Both branches are embracing this technology to gain competitive advantages.

Optimizing Performance Through Lightweighting and Complex Geometries

One of the distinctive advantages of additive manufacturing is its ability to create parts with highly complex internal geometries that are impossible or cost-prohibitive with traditional methods. This includes lattice structures and internal channels which can significantly reduce the weight of a component while maintaining or even increasing its structural integrity. For airborne weapon systems, weight reduction translates directly into improved range, payload capacity, and maneuverability.

For ground-based systems, lighter components can enhance mobility and reduce the logistical burden of transportation. Furthermore, 3D printing allows for the integration of multiple functions into a single part, reducing assembly complexity and the number of individual components required. This streamlining not only improves reliability but also simplifies the supply chain for maintenance and repair, a critical factor in wartime scenarios.

- Reduced Weight: Crucial for aircraft and soldier equipment.

- Integrated Functionality: Combining multiple parts into one print.

- Optimized Heat Exchange: Printing complex internal cooling channels.

- Rapid Tooling Creation: Producing specialized jigs and fixtures quickly.

The ongoing research into generative design, where AI algorithms create optimized designs for 3D printing, promises even further advancements in performance and material utilization. This combination of advanced design and manufacturing techniques is setting new benchmarks for weapon system capabilities.

Challenges and the Path Forward for Widespread Adoption

Despite the undeniable advantages, the widespread adoption of 3D printing within the US military, particularly for weapon systems, is not without its challenges. These include issues related to material qualification, intellectual property concerns, quality assurance, scalability for mass production, and integrating additive manufacturing seamlessly into existing maintenance and supply chain protocols.

The stringent requirements for military-grade equipment mean that every 3D-printed component must undergo rigorous testing and certification. Ensuring that a part printed in a remote location meets the exact same specifications and performance standards as one produced in a centralized facility is a complex undertaking. Addressing these challenges requires continued investment in research, standardized testing procedures, and robust digital ecosystems to manage designs and production data securely.

Intellectual Property and Data Security

One of the most pressing concerns surrounding the digital nature of 3D printing is intellectual property (IP) protection and data security. Weapon system designs are highly sensitive, and transmitting these digital files for printing, especially in distributed or forward-deployed environments, introduces potential vulnerabilities. Ensuring that these digital blueprints are secure from cyber threats, unauthorized access, or replication is paramount to national security.

The DoD is actively developing secure digital manufacturing ecosystems that incorporate encryption, blockchain technologies, and access controls to mitigate these risks. Establishing clear guidelines for data handling and material traceability is essential to maintain control over sensitive designs and prevent the proliferation of unauthorized weapon components. This secure digital backbone is critical for realizing the full potential of distributed 3D manufacturing.

Quality Assurance and Certification

For any component destined for a weapon system, quality assurance and certification are non-negotiable. With 3D printing, this process is complicated by the myriad of variables involved: printer type, material batch, environmental conditions, and post-processing techniques. Ensuring consistency and reliability across these variables for every printed part is a significant hurdle.

The military is investing in advanced non-destructive testing methods, in-situ monitoring during the printing process, and sophisticated digital twin technologies to track a part’s lineage and performance characteristics. Developing standardized qualification procedures and robust quality control frameworks is essential to build confidence in 3D-printed parts for critical applications, moving beyond prototyping to full-scale deployment in the most demanding scenarios.

Future Outlook: Hyper-Personalized Warfare and Adaptive Responses

The trajectory of 3D printing within the US military points towards a future of hyper-personalized warfare and incredibly adaptive response capabilities. As the technology continues to mature, we can anticipate a greater proliferation of 3D printing capabilities down to the squad level, empowering soldiers with unprecedented on-demand manufacturing options. This will not only impact weapon systems but also protective gear, medical supplies, and general equipment, allowing for rapid, situation-specific customization tailored to immediate tactical needs.

The integration of artificial intelligence and machine learning with additive manufacturing will likely lead to generative designs that automatically optimize performance based on mission parameters, further accelerating innovation. Furthermore, the development of multi-material printing will enable the creation of highly integrated, multi-functional components, dramatically reducing complexity and enhancing system capabilities.

Autonomous Repair and Responsive Logistics

Looking ahead, 3D printing is a foundational technology for the vision of autonomous repair and truly responsive logistics. Imagine weapon systems capable of self-diagnosing damage and then initiating the additive manufacturing of replacement parts, either autonomously or with minimal human intervention. This would drastically reduce downtime, maintenance costs, and the logistical footprint required to sustain forces globally.

The ability to push production capabilities ever closer to the point of need – even directly into contested zones – transforms tactical and strategic planning. This decentralized, on-demand manufacturing model will grant military forces an unparalleled level of agility and resilience, ensuring that they can adapt to unforeseen challenges and maintain operational superiority in an increasingly complex global security environment.

Integration with Digital Engineering and AI-Driven Design

The true potential of 3D printing in the US military is unlocked when it is fully integrated with broader digital engineering initiatives and AI-driven design processes. Digital engineering involves creating and maintaining a comprehensive digital model of a system throughout its entire lifecycle, from concept to disposal. This “digital thread” allows for seamless data exchange and collaboration across all stages of development and deployment.

When combined with AI, this digital approach fosters a revolutionary design paradigm. AI algorithms can rapidly explore vast design spaces, optimize topologies for strength and weight, and even predict manufacturability, all before a single physical prototype is ever printed. This synergistic relationship between digital engineering, AI, and additive manufacturing represents the future of defense innovation. It promises not just faster prototyping but fundamentally superior weapon systems, designed and produced with unprecedented efficiency and precision.

This integration aims to create a closed-loop system where data from field performance feeds directly back into the design process, allowing for continuous improvement and adaptation. This dynamic feedback loop ensures that weapon systems are not just rapidly prototyped but are also continually evolving to meet the latest threats and operational requirements.

| Key Application | Brief Description |

|---|---|

| 🚀 Rapid Prototyping | Accelerates design iterations and testing of new weapon systems, reducing development time. |

| 🛠️ On-Demand Parts | Field fabrication of spare parts, tools, and custom components, enhancing readiness. |

| 💡 Design Optimization | Enables creation of complex, lightweight, and multi-functional weapon system components. |

| 🔒 Enhanced Logistics | Reduces reliance on traditional supply chains, improving self-sufficiency in remote areas. |

Frequently Asked Questions About Military 3D Printing

The US military is 3D printing a wide range of components, from internal structural parts and casings to specialized jigs, fixtures, and replacement pieces for obsolete systems. This includes both plastic and metal components, selected based on specific application requirements for strength, heat resistance, and weight.

3D printing significantly accelerates weapon system development by enabling rapid design iterations and prototyping. Engineers can quickly print and test multiple versions of a component, identifying and resolving issues much faster than with traditional manufacturing methods, thereby shortening the overall development cycle.

While primarily known for prototyping, 3D printing is increasingly used for functional components and spare parts in active weapon systems. Advancements in materials and printing techniques allow for the production of durable, mission-critical parts that meet stringent military specifications, moving beyond just initial conceptualization.

Key challenges include ensuring consistent quality and certification of printed parts, protecting intellectual property and data security for sensitive designs, and scaling up production for large-scale military applications. Integrating these new processes into existing complex logistics chains also presents a significant hurdle.

3D printing revolutionizes military logistics by enabling on-demand part fabrication, reducing reliance on lengthy traditional supply chains. This significantly improves operational readiness, allowing forces to repair equipment and replace parts quickly, even in remote or austere environments, thereby minimizing downtime.

Conclusion

The integration of 3D printing within the US military, particularly for rapid prototyping of weapon systems, marks a profound shift in defense innovation and readiness. This additive manufacturing capability is not merely an incremental improvement; it is a transformative force, enabling unprecedented speed in design iteration, on-demand component fabrication, and enhanced logistical resilience. As material science and digital engineering continue to evolve, 3D printing promises to deliver an agile, adaptive, and technologically superior future for the US Armed Forces, ensuring they remain at the vanguard of global defense capabilities.