US Military’s 3D Printing Revolution: From Prototypes to Production

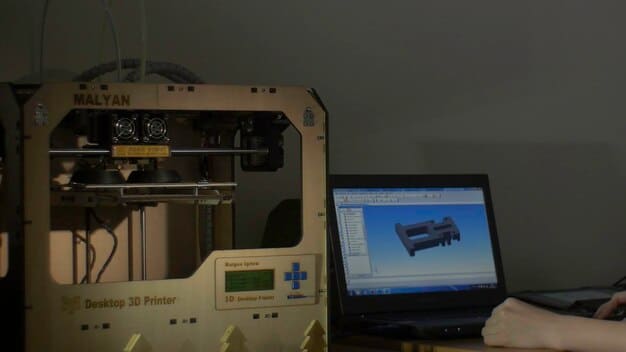

The US military is rapidly integrating 3D printing, or additive manufacturing, to transform its defense capabilities by accelerating prototyping, bolstering supply chain resilience, and enabling on-demand production of critical components directly in forward operating environments.

The landscape of modern defense is constantly evolving, driven by the imperatives of adaptability, speed, and efficiency. At the forefront of this transformation is additive manufacturing, commonly known as 3D printing. This groundbreaking technology is redefining How the US Military is Utilizing 3D Printing for Rapid Prototyping and Manufacturing, offering unprecedented agility in design, production, and logistical support across its diverse branches. From enhancing battlefield readiness to revolutionizing equipment maintenance, 3D printing is rapidly becoming an indispensable tool in the military’s arsenal, promising a future where innovation and responsiveness converge to meet complex global challenges with unparalleled effectiveness.

The Strategic Imperative: Why 3D Printing Matters to the US Military

The US military operates in an increasingly complex and unpredictable global environment, where the ability to adapt quickly and maintain operational superiority is paramount. Traditional manufacturing and supply chain models often fall short in meeting these dynamic demands, leading to delays, high costs, and logistical vulnerabilities. This is where 3D printing emerges as a game-changer, offering solutions that directly address critical strategic imperatives. It enables the military to overcome geographical limitations, accelerate developmental cycles, and ensure that personnel have the right tools and parts precisely when and where they are needed, enhancing readiness and mission success.

Overcoming Supply Chain Fragilities

A significant advantage of additive manufacturing lies in its capacity to mitigate the inherent fragilities of global supply chains. Relying on centralized manufacturing facilities and complex international logistics networks can expose the military to disruptions caused by geopolitical tensions, natural disasters, or even pandemics. 3D printing facilitates localized production, reducing reliance on distant suppliers and lengthy shipping routes. This distributed manufacturing capability means that critical parts can be fabricated on-demand at bases, on ships, or even in forward operating positions, drastically shortening lead times and minimizing the risk of supply interruptions.

Enhanced Expeditionary Capability

The nature of modern warfare often requires rapid deployment and sustainment in austere or remote environments. Traditional logistics, involving the transport of vast inventories, can be cumbersome and resource-intensive. 3D printing significantly bolsters expeditionary capabilities by allowing for the creation of bespoke tools, repair parts, and even customized protection gear directly in the field. This capability reduces the logistical footprint, lessens the weight and volume of equipment that needs to be transported, and empowers units to become more self-sufficient. This not only improves operational efficiency but also enhances responsiveness to unforeseen challenges on the ground.

* Reduced logistical dependence in remote areas.

* Ability to print mission-specific tools and parts on-site.

* Lower overall weight and volume of transported inventory.

The strategic push towards integrating 3D printing is not merely about adopting new technology; it’s about fundamentally rethinking how the US military designs, produces, and sustains its operations. It represents a paradigm shift from a “stockpile and resupply” model to an “on-demand and adapt” approach, allowing for unparalleled flexibility and resilience in the face of evolving threats and operational demands. This shift ensures continuous innovation and superior operational readiness, crucial elements for maintaining a decisive edge in the global arena.

Revolutionizing Prototyping: Speed, Iteration, and Cost Efficiency

The evolution of military hardware, from advanced weaponry to specialized vehicles and personal protective equipment, has historically been a protracted and expensive process. Traditional prototyping methods often involve lengthy design cycles, costly tooling, and sequential iterations that slow down development and escalate expenses. 3D printing has fundamentally reshaped this landscape, ushering in an era of rapid prototyping characterized by unparalleled speed, cost-efficiency, and design flexibility. This transformative capability allows military engineers and designers to move from concept to physical model in record time, accelerating the innovation pipeline.

For instance, the ability to quickly produce a physical representation of a component significantly aids in the identification and rectification of design flaws early in the development phase. This iterative design process, facilitated by 3D printing, means that multiple design variations can be tested and refined in parallel, optimizing performance and reducing the likelihood of costly redesigns later on. What once took weeks or months can now be achieved in days, or even hours, providing a distinct advantage in the fast-paced world of defense innovation.

Accelerating Design-to-Deployment Cycles

One of the most profound impacts of 3D printing on military prototyping is the dramatic reduction in the “design-to-deployment” cycle. In an operational environment where technological superiority can be fleeting, speed matters. With 3D printing, engineers can rapidly design a new part, print a prototype, test it, and implement modifications based on real-world feedback, all within an incredibly compressed timeframe. This agility is critical for developing responses to emergent threats or for tailoring existing equipment to highly specific mission requirements.

* Rapid creation of functional prototypes for immediate testing.

* Concurrent testing and modification of multiple designs.

* Reduced lead times for specialized equipment and tools.

The cost efficiency of 3D printing in prototyping is equally significant. Eliminating the need for expensive molds and specialized tooling for each iteration drastically lowers development costs. Furthermore, the ability to print only the necessary amount of material reduces waste, contributing to more sustainable practices. As the technology matures, and materials become more diverse and robust, the scope for intricate and highly functional prototypes continues to expand, allowing the military to push the boundaries of design and engineering without the prohibitive costs and delays associated with conventional methods.

Manufacturing on Demand: From Parts to Platforms

The concept of “manufacturing on demand” is rapidly transforming military logistics and operational readiness, moving beyond simple prototyping to the direct fabrication of end-use parts and even larger components. This strategic shift, empowered by additive manufacturing, means that the US military is increasingly capable of producing critical items, from spare parts for aging equipment to new tactical gear, precisely when and where they are needed, rather than relying on a centralized, often slow, supply chain. This distributed manufacturing capability introduces unprecedented levels of agility and resilience into military operations.

Enhancing Maintenance and Sustainment

Maintaining a vast inventory of diverse military equipment, some of which may be decades old, presents significant logistical challenges. Parts can become obsolete, manufacturers may cease production, or the supply chain can be disrupted. 3D printing offers a viable solution by enabling the on-demand creation of repair parts. This capability extends the lifespan of existing equipment, reduces the need for extensive stockpiling, and significantly cuts down on downtime for critical assets. Whether it’s a specialized bracket for an aircraft or a hard-to-find component for a ground vehicle, 3D printing provides a pathway to rapid repair and sustainment.

Consider the implications for naval vessels deployed far from traditional industrial bases. A broken part could put a ship out of commission for days or weeks awaiting a replacement. With 3D printing capabilities on board, a new component could be designed, printed, and installed within hours, ensuring continuous operational readiness. This principle applies across all branches, allowing for expeditionary repairs and custom modifications that were previously impossible or impractical in forward operating environments.

* Reduced downtime for critical military assets.

* Extended lifespan of aging equipment through part fabrication.

* Minimized reliance on external, potentially vulnerable, supply chains.

* Rapid repair solutions in remote or deployed locations.

The shift towards on-demand manufacturing is not limited to small parts. As 3D printing technology scales and matures, the ability to create larger, more complex structures is emerging. This includes components for vehicles, drones, and even elements for temporary shelters or infrastructure in contested zones. The strategic advantage lies in the ability to rapidly deploy custom solutions that fit exact mission specifications, adapting to dynamic battlefield conditions with unprecedented speed and precision, ultimately bolstering the military’s strategic adaptability and operational effectiveness.

Advanced Materials and Multi-Material Printing: Expanding Capabilities

The true potential of 3D printing for the US military extends beyond merely replicating existing parts; it lies in the capability to innovate with advanced materials and to combine different materials within a single print. This frontier of additive manufacturing is opening doors to components with enhanced properties—lighter, stronger, more durable, and possessing integrated functionalities that were previously unattainable through conventional manufacturing techniques. The exploration of these materials and multi-material processes is critical to developing next-generation military hardware.

One significant area of focus is the development of high-performance polymers, metals, and composites specifically engineered for military applications. This includes materials that can withstand extreme temperatures, resist corrosion, absorb impact more effectively, or even incorporate stealth properties. For instance, the ability to 3D print components from specialized alloys means parts can be optimized for specific stress loads, leading to lighter, yet stronger, structures for aircraft or armored vehicles, directly impacting fuel efficiency and protection levels.

Integrating Sensors and Electronics

The advent of multi-material printing is particularly exciting because it allows for the integration of disparate functionalities within a single manufactured object. Imagine a structural component for a drone that also contains embedded sensors for real-time diagnostics, or a piece of armor designed with integrated heating elements to prevent cold weather performance degradation. This capability streamlines manufacturing processes, reduces assembly time, and creates highly resilient and intelligent systems.

* Development of lighter, stronger, and more durable components.

* Integration of electronic circuits and sensors directly into parts.

* Creation of materials with tailored thermal, electrical, or stealth properties.

* Reduced number of assembly steps and enhanced system reliability.

The research and development in this area are continuous, with military laboratories and defense contractors actively exploring new material combinations and printing techniques. This includes investigating “smart materials” that can change properties in response to external stimuli, or bio-inspired structures that mimic natural designs for optimal performance. By pushing the boundaries of what is possible with advanced materials and multi-material printing, the US military is not just improving existing equipment but is fundamentally reimagining the very nature of future defense technologies, leading to more capable, resilient, and adaptive systems on the battlefield.

Logistics and Supply Chain Optimization: A Distribution Revolution

The US military’s logistical operations are among the most complex in the world, spanning continents and requiring the movement of vast quantities of supplies, equipment, and personnel. Traditional supply chains, optimized for mass production and centralized warehousing, often struggle with the dynamic and unpredictable demands of military operations, leading to inefficiencies, delays, and significant costs. Additive manufacturing offers a revolutionary approach to logistics and supply chain optimization, promising a leaner, more resilient, and responsive support system for all branches of the armed forces.

The core of this revolution lies in the ability to decentralize manufacturing. Instead of shipping parts from distant factories, 3D printing allows for the local production of components, right at the point of need. This drastically reduces transit times, inventory holding costs, and the associated carbon footprint. For example, rather than maintaining a warehouse full of spare parts that may or may not be used, military units can access a digital library of designs and print a component only when it is required. This “digital inventory” concept transforms logistics from a physical movement of goods to a rapid transfer of data.

Forward-Deployed Manufacturing Hubs

The concept of deploying 3D printing capabilities to forward operating bases, naval vessels, and even mobile units is gaining traction. These mini-factories can produce custom tools, repair parts for vehicles or aircraft, and even specialized equipment tailored to specific mission requirements. This reduces the logistical tail, making units more self-sufficient and responsive. In a crisis, the ability to print critical parts on-site can mean the difference between operational readiness and significant downtime.

Furthermore, 3D printing supports the concept of “just-in-time” supply, minimizing waste and optimizing resource allocation. It also provides an unparalleled level of resilience against supply chain disruptions, whether from natural disasters, geopolitical events, or cyberattacks. By diversifying manufacturing points and reducing reliance on single-source suppliers, the military can ensure continuity of operations even in challenging circumstances.

* Transition from physical inventory to digital design files.

* Reduced shipping costs and environmental impact.

* Creation of agile, forward-deployed manufacturing capabilities.

* Enhanced resilience against global supply chain disruptions.

The optimization extends beyond just parts; it influences the very strategy of sustainment. Military planners can now consider highly flexible and adaptive maintenance strategies, integrating on-demand manufacturing into their operational plans. This allows for more targeted resource allocation, quicker adaptation to unforeseen equipment failures, and a general shift towards a more proactive and predictive approach to military logistics. The result is a more agile, cost-effective, and robust supply chain that can better support the US military’s global operations.

Challenges and the Path Forward: Scaling and Integration

While the benefits of 3D printing for the US military are substantial and transformative, the path to full-scale integration is not without its challenges. Overcoming these hurdles requires a concerted effort in research, development, policy, and training. The journey from localized prototyping to widespread manufacturing on demand involves significant technical, logistical, and cultural shifts within a vast and complex organization. Addressing these challenges is crucial for realizing the full potential of additive manufacturing in defense.

One primary technical challenge is the standardization and qualification of 3D-printed parts. For critical components, ensuring that a 3D-printed part meets the same rigorous performance and safety standards as a traditionally manufactured one is paramount. This involves developing robust testing protocols, material property databases, and certification processes that instill confidence in the reliability and durability of additive solutions. The diverse range of materials and printing technologies further complicates this standardization effort.

Workforce Development and Training

A significant non-technical challenge lies in workforce development. The successful implementation of 3D printing across the military requires a skilled workforce capable of operating and maintaining the printers, designing printable parts, and understanding the nuances of additive manufacturing processes. This necessitates investing in comprehensive training programs for engineers, logisticians, and warfighters, embedding additive manufacturing literacy at various levels of military education and training.

* Establishing universal standards for 3D-printed part qualification.

* Developing secure digital repositories for design files.

* Training a new generation of military personnel in additive manufacturing.

Integrating 3D printing into existing logistical and maintenance workflows also presents a complex interoperability challenge. Legacy systems, IT infrastructure, and established procurement processes must adapt to accommodate the decentralized and on-demand nature of additive manufacturing. This includes developing secure digital supply chains, protecting intellectual property of design files, and ensuring seamless communication between designers, manufacturers, and end-users. Despite these challenges, the military’s commitment to advancing 3D printing is clear, with continued investment in research, pilot programs, and strategic partnerships aiming to overcome these obstacles. The path forward involves a systematic approach to scaling up capabilities, refining processes, and fostering an innovative culture that embraces the transformative power of additive manufacturing to secure a strategic advantage.

Cybersecurity and Intellectual Property: Protecting Digital Blueprints

As the US military increasingly relies on 3D printing for rapid prototyping and manufacturing, the integrity and security of its digital design blueprints become paramount. The transition from physical inventories to digital files introduces a new frontier of vulnerabilities related to cybersecurity and intellectual property (IP). Protecting these digital assets is not merely a matter of data security; it’s a critical component of national security, ensuring that adversaries cannot compromise the design, function, or availability of essential military components. The implications of a compromised design could range from equipment failure to strategic disadvantages on the battlefield.

Ensuring the authenticity and integrity of design files is a complex endeavor. A malicious actor could inject flaws into a digital blueprint that lead to a critical part failing under stress, or subtly alter specifications to degrade performance. This emphasizes the need for robust encryption, authentication protocols, and secure network infrastructures that protect design files from unauthorized access or modification from the moment they are conceived to when they are printed. The entire digital thread, from design software to the printing machine’s firmware, must be secured.

Managing Intellectual Property in an Open Environment

The collaborative nature of 3D printing development, involving military, industry, and academia, also raises complex intellectual property challenges. While sharing designs can accelerate innovation, it also requires strict frameworks to define ownership, usage rights, and export controls for sensitive military designs. The balance between fostering innovation through collaboration and safeguarding critical defense IP is delicate and requires proactive policy development.

* Implementing end-to-end encryption for all digital design files.

* Developing secure blockchain technologies for design provenance and integrity.

* Establishing clear IP policies for collaborative 3D printing projects.

* Training personnel on secure digital practices for additive manufacturing.

Furthermore, the concept of a “digital warehouse” for military parts, while highly efficient, means that a single breach could compromise a vast array of critical components. Therefore, the military is investing in advanced cybersecurity measures specifically tailored to additive manufacturing ecosystems. This includes intrusion detection systems, secure data storage solutions, and stringent access controls. The goal is to create a resilient and trusted environment where digital blueprints can be shared, stored, and printed with absolute confidence in their security and authenticity, safeguarding the military’s technological edge in a new era of digital manufacturing.

| Key Benefit | Brief Description |

|---|---|

| 🚀 Rapid Prototyping | Accelerates design, testing, and iteration of military components, reducing development cycles significantly. |

| 🛠️ On-Demand Manufacturing | Enables production of critical parts in the field, reducing supply chain reliance and enhancing readiness. |

| 💡 Material Innovation | Allows for creation of lighter, stronger, multi-functional components with specialized properties. |

| 🔒 Enhanced Security | Focus on protecting digital blueprints and supply chains against cyber threats and IP infringements. |

Frequently Asked Questions about 3D Printing in the Military

3D printing, or additive manufacturing, is a process where a three-dimensional object is created by building successive layers of material. In military operations, it allows for rapid prototyping of new equipment, on-demand manufacturing of spare parts in remote locations, and the creation of specialized tools, significantly enhancing agility and logistical efficiency.

By enabling localized and on-demand production, 3D printing reduces the military’s reliance on centralized manufacturing and extensive global shipping. This decentralization minimizes vulnerability to supply chain disruptions caused by geopolitical events, natural disasters, or logistical bottlenecks, ensuring crucial parts are available whenever needed.

The military utilizes a wide range of materials for 3D printing, including high-performance polymers, various metals (like titanium and aluminum alloys), and composites. Ongoing research explores advanced materials engineered for specific military needs, such as those with enhanced strength, stealth properties, or integrated electronic capabilities for functional components.

Rapid prototyping with 3D printing dramatically accelerates the design, testing, and iteration cycles for new military equipment. It allows engineers to quickly produce physical models, identify and rectify design flaws early, and optimize performance in a fraction of the time and cost compared to traditional methods, speeding up deployment of critical technologies.

With digital blueprints now critical assets, cybersecurity concerns include protecting design files from unauthorized access, modification, or intellectual property theft. Ensuring the integrity and authenticity of these digital assets is vital to prevent compromised part performance or strategic disadvantages, requiring robust encryption and secure digital supply chains.

Conclusion

The integration of 3D printing is unequivocally reshaping the operational capabilities and strategic agility of the US military. From the remarkable acceleration of prototyping cycles to the profound optimization of logistics and supply chains, additive manufacturing stands as a cornerstone of modern defense innovation. While significant challenges related to standardization, workforce development, and cybersecurity remain, the commitment to overcoming these hurdles is evident. As this transformative technology continues to evolve, it promises a future where the US military can respond with unprecedented speed, resilience, and adaptability to an ever-changing global security landscape, ultimately enhancing readiness and maintaining a decisive technological edge for decades to come.